Description

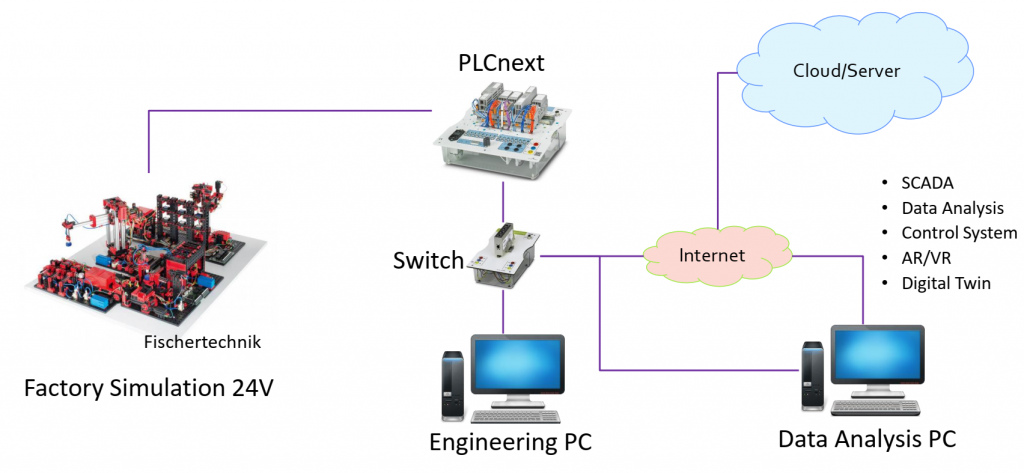

The Smart Factory 4.0 Simulation learning environment is used in learning and understanding industry 4.0 applications and depicts the ordering process, the production process and the delivery process in digitized and networked process steps. The models included 4 main stations: Sorting Line With Color Detection, Multi Processing Station With Oven, Automated High-Bay Warehouse, and Vacuum Gripper Robot. This set needs 2 PLCnext for covering the required I/Os.

Virtual Lab Tour:

Description:

• AGV transport objects from station A to station B.

• At the station, the robot arm picks and places objects, filling in the tray.

• Process controlled by PLC through PROFINET and monitored with PC.

• AGVs communicate with PC via WIFI.

Virtual Lab Tour:

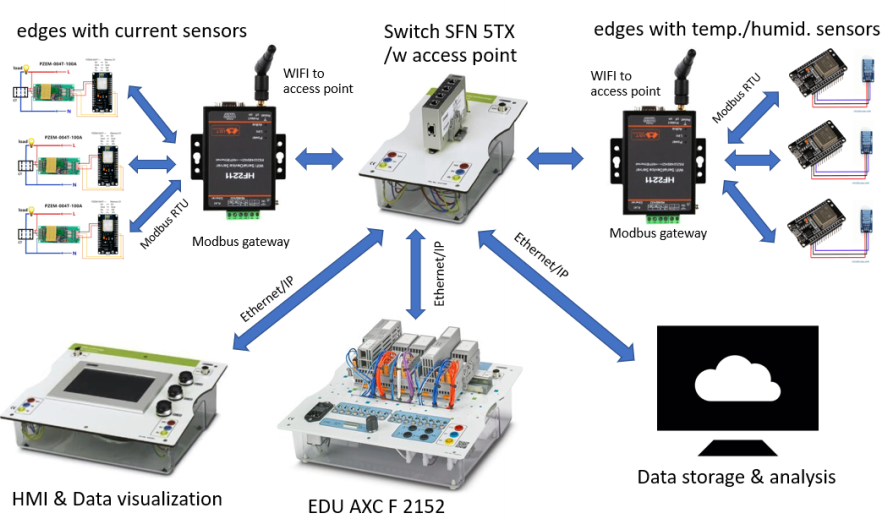

Description:

KMITL ETAT Training Center will use PLCnext for training students how to control devices in Smart Home and Smart City concepts. The lab is setup at the room 106 in SC08 building at School of Science, KMITL.

Virtual Lab Tour:

Description:

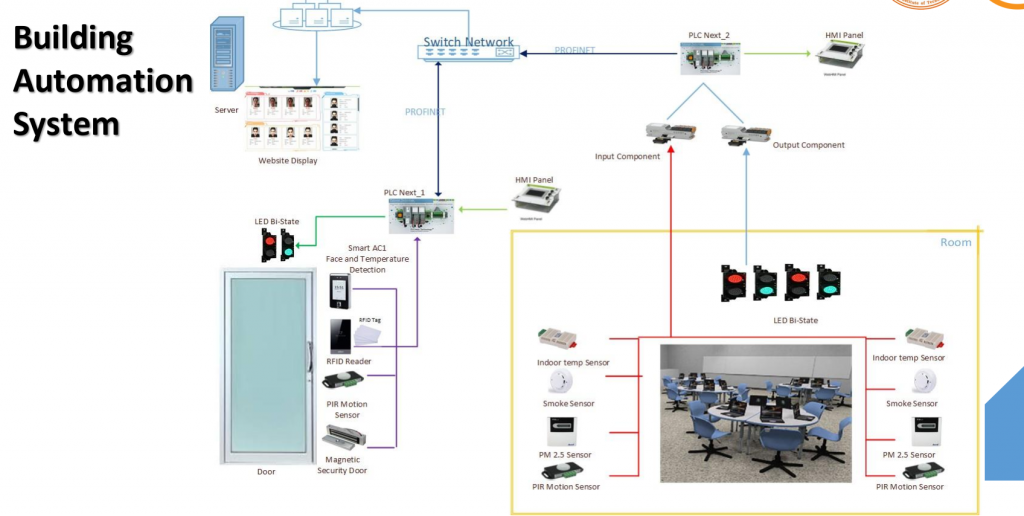

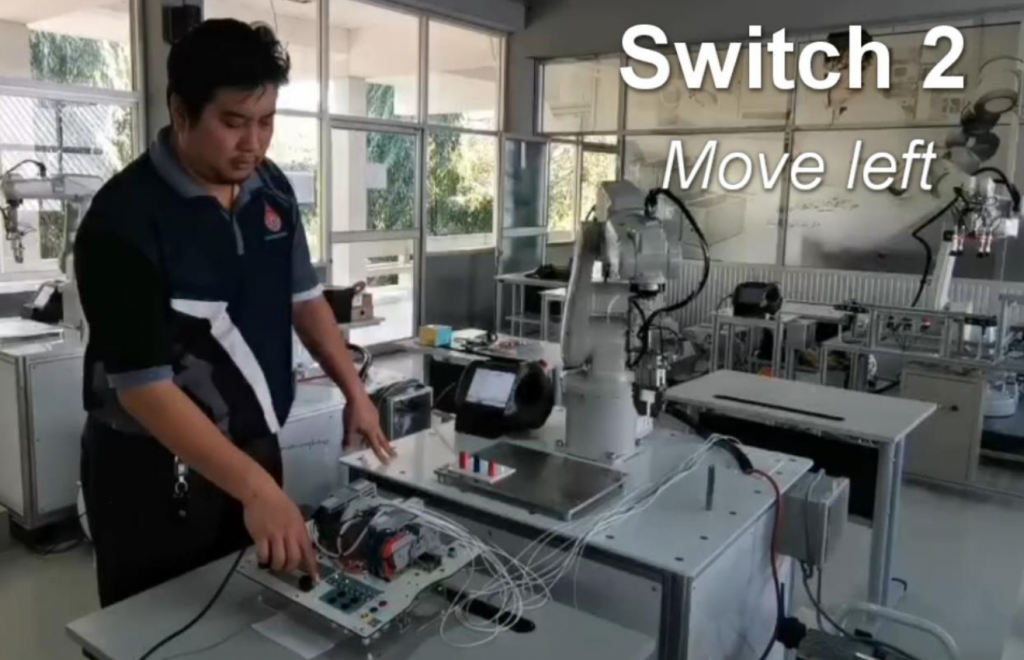

We concentrate on bringing PLCnext to control robots and automation system. In this training center, students will learn how to program robot arms using standard PLC programming language. They will also get the training of industrial robots and automation.

Virtual Lab Tour:

Description:

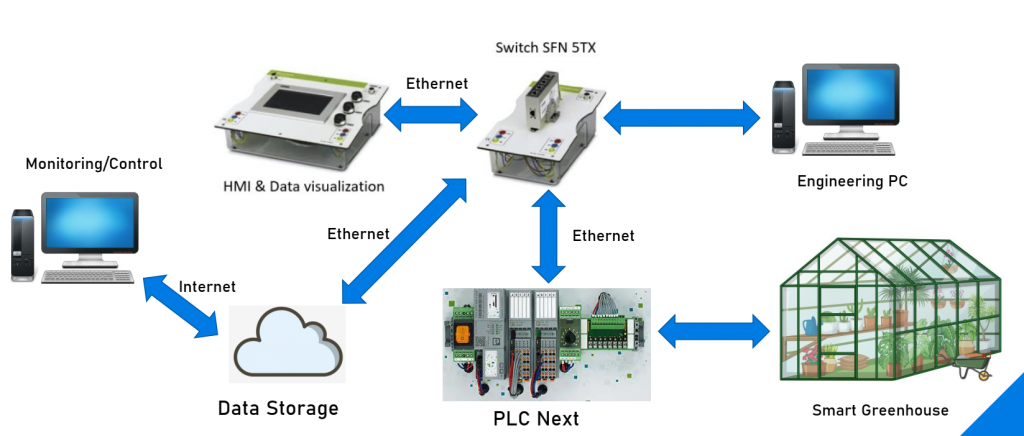

The Smart Agriculture learning environment

▪ is used to learning and understanding about Smart Agriculture(Smart Farming).

▪ depicts to check the suitable environment for smart farming using IOT Devices.

Models included 1 main stations:

▪ Light Sensor

▪ Temperature and Humidity Sensor

▪ Soil Moisture Sensor

▪ CO2 Sensor

▪ EC (Electric Conductivity) Sensor

Virtual Lab Tour:

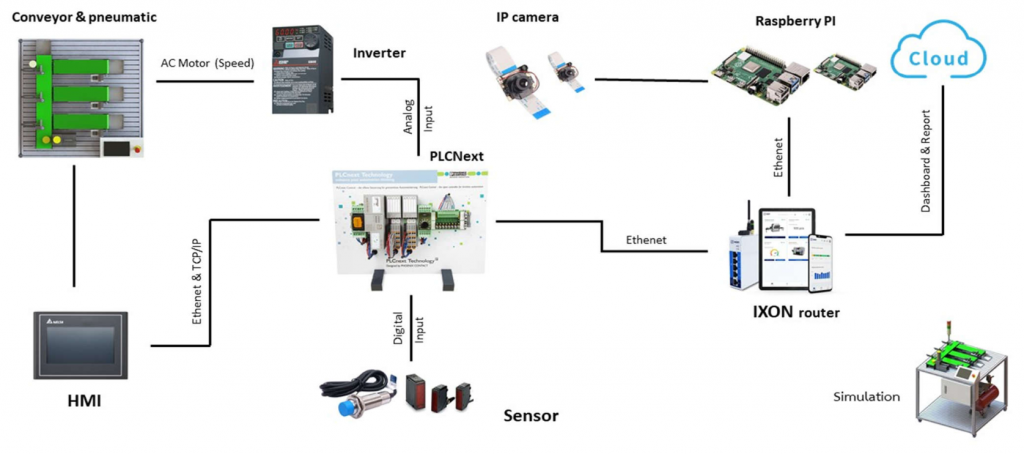

Description:

Practice set to develop programming, control and display skills over the Internet. (IoT) With an Automated Controlled Sorting Conveyor Simulation System. The unit is meant to connect to PCLnext. The communication should be RJ45 to issue a command with a web interface. Once it is properly

installed our cloud platforms can receive data fire from the device.

Virtual Lab Tour: